We just came back from the annual Barber Vintage Festival in Birmingham, AL and Rick did a couple seminars on vintage charging systems. For those of you not able to attend, we wanted to publish a couple posts to sum up what he had to say:

Let’s start off with the basic terms that we use: Volts, Amps, & Watts: Volts x Amps = Watts. We’re going to use a water analogy to explain this concept.

Volts = the amount of pressure in the pipes

Amps = the size of the pipes; basically the volume it can run

Watts = the amount of usable power in a given time/flow

So the size of the pipe (Amps) x the amount of pressure inside the pipe (Volts) = the amount of usable power supplied (Watts).

Moving on to Good Practices in our Industry.

- You want to make sure you keep all of your connections clean & free from corrosion, dirt & debris.

- When making repairs to wiring, ALWAYS make sure you’re using the correct “B” crimp illustrated below. We sell a crimping tool that does this & so do a couple other people out there. Just make sure you get one that does the “B” crimp!

- Use the correct wire stripping tool. You don’t want one that cuts into the actual wire, just strips off the insulation.

- Use the correct wire – don’t use stereo wire, please! We use crosslink polyethylene in the production of all our parts. It protects against moisture & oil and has a heat rating of 125 degrees C.

- Correct solder joints & repairs. When you need to solder your wires, practice a couple times before you do the actual job. You want the solder to mesh into the wires. You don’t want a big glob of solder or not enough solder so some of the wires are still exposed. See the illustration below for proper colder joints.

Basic Charging Systems: Field Coil vs Permanent Magnet

- The field coil system, found in the Honda early to mid 1980s CB750/900, Yamaha XS650/750/1100s and early Kawasaki 3 cylinders. The “electro-magnet” is of a variable strength. So it puts out the amount of power the bike is using & enough to keep the battery charged. This is the system that cars are using with their alternators.

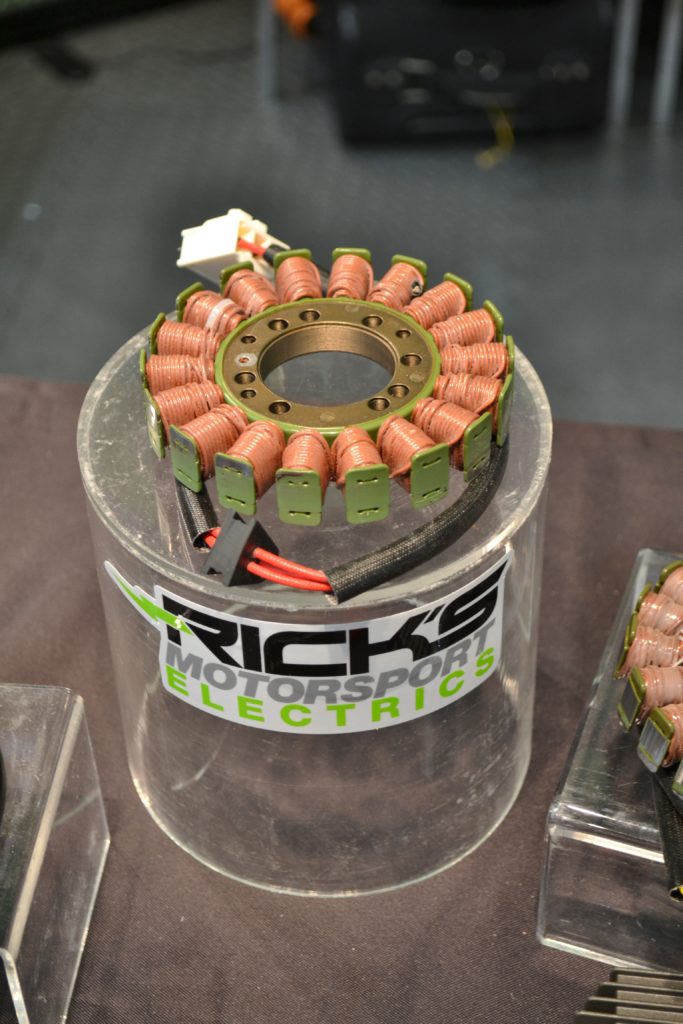

- The permanent magnet systems (which mostly all modern sport bikes have moved to) is exactly that. A permanent magnet rotates inside or outside of the stator. The amount of power that comes out is governed by the design of the stator/rotor and how fast it rotates. The strength level is FIXED, not variable like the field coil rotor.

Stator from a permanent magnet charging system

Hope this general introduction has helped you guys understand some of the good practices we like to use whenever working with electrical components. We will get into more specific “common issues” that we see here all the time with the charging systems on these vintage bikes in Part 2 next week. Stay tuned…